HOW TO INSTALL ACP DECOBOND

cara pasang acp, pemasangan acp, instalasi acp, pasang acp, cara pasang aluminium composite panel, pemasangan aluminium composite panel

FABRICATION

Decobond is versatile formability, it can be bent, cut, and formed according to your architectural need.

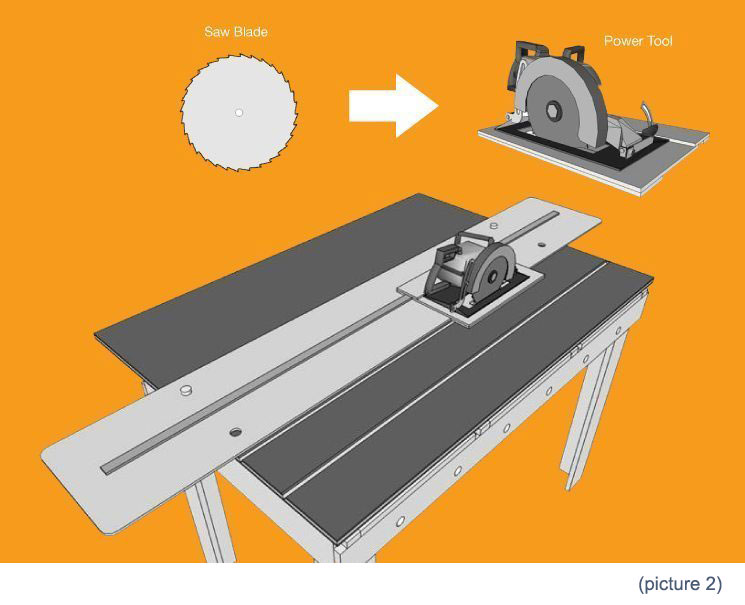

01 CUTTING

Decobond can be cut using a wide variety of machines and tools such as table saws, hand circular saws, panel saws, shear cutting. A suitable saw blade is a carbide-tipped blade for aluminum or plastic use. (see picture 2)

02 ROUTING & GROOVING

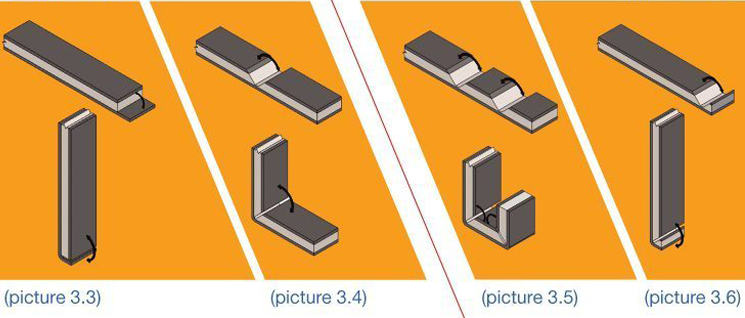

Routing, grooving, and folding are usually needed to form a variety shapes or sizes. In this process, the back surface of Decobond is cut forming a V-shaped or rectangular one, using disc or end milling cutter. The front surface of the aluminum cover and part of the core are retained to enable it to be folded.

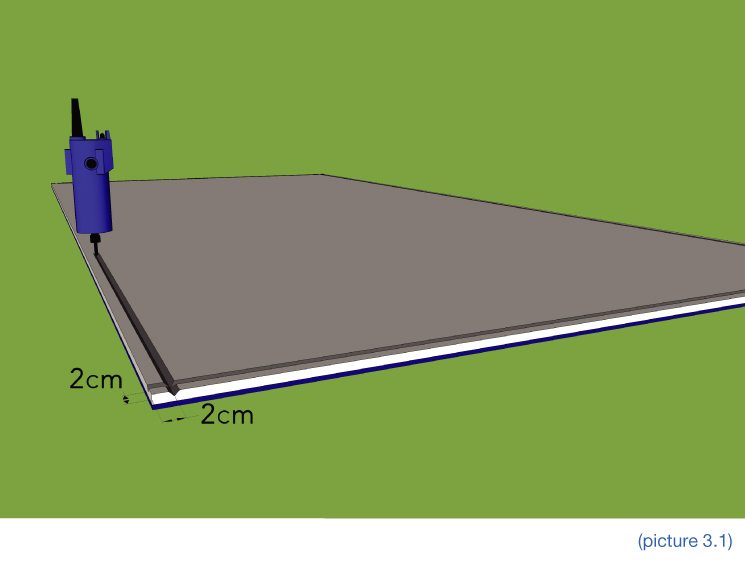

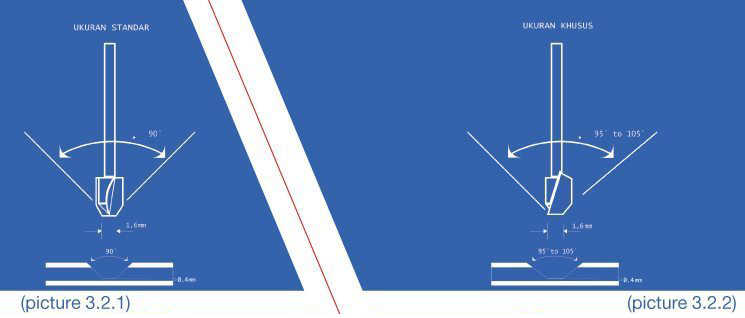

The recommended minimum distance of the grove line from the panel edge is 20mm. (see picture 3.1) Please ensure to leave at least 0.4mm thickness of the core. (see picture 3.2.1 and picture 3.2.2)

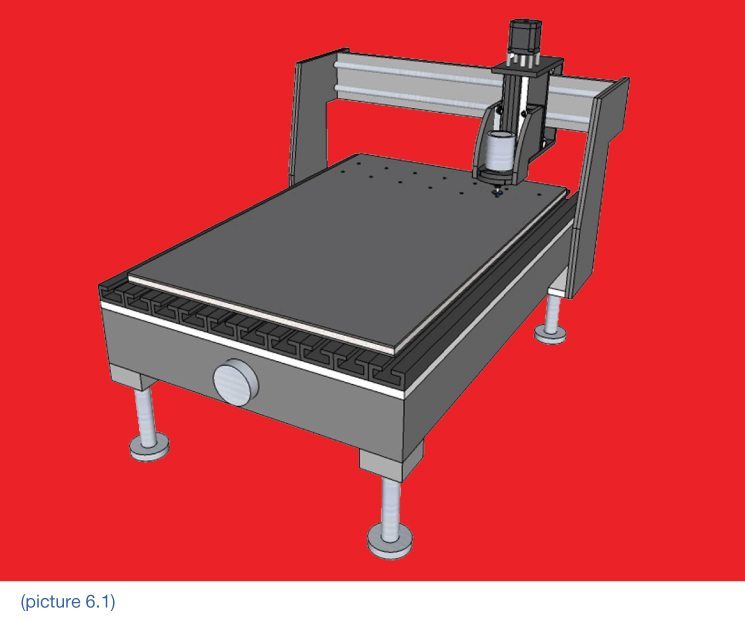

Using the computerized CNC machine to do the routing or grooving process is recommended to ensure the accuracy, and efficiency. Decobond folding process is shown in picture 3.3 – 3.6

03 BENDING

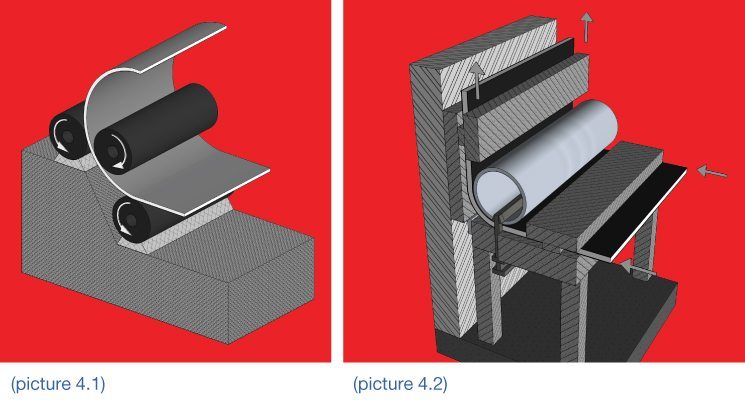

A. Bending process using pyramid roller machine will allow various bending radius (see picture 4.1)

B. Using clamped pipe machine (see picture 4.2). Note: max bending radius is 30 degree.

04 DRILLING

Decobond can be drilled using drilling tool for plastic or aluminum (see picture 5.1)

05 PUNCHING

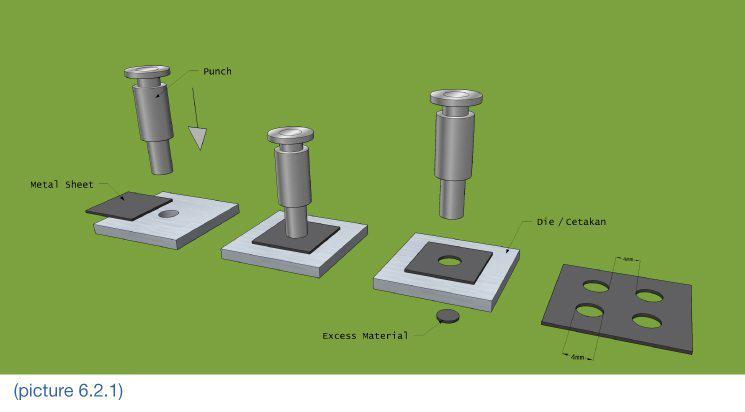

A punching press can be used for notching and cutting out. The suitable clearance between punch and die is 0.1mm.(see picture 6.1)

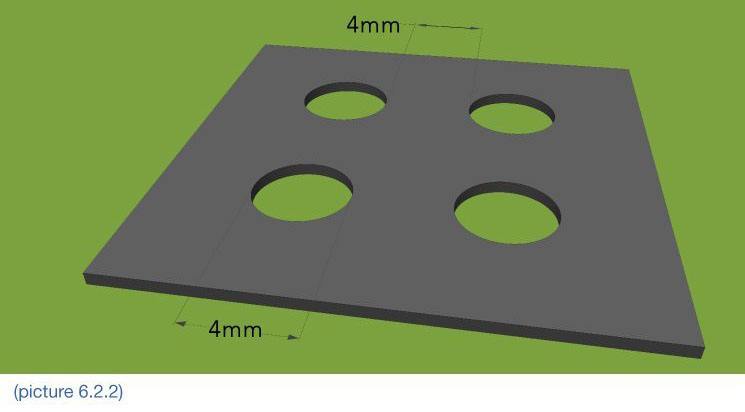

For interior and ceiling design, Decobond can be perforated using CNC puncher (see picture 6.1). The minimum diameter of a hole can be punched is 4mm, and the minimum distance between holes is also 4mm. (see picture 6.2.1 – 6.2.2)

The best result is achieved using a single punch, multi punch is more economical, but further flatness processing is required to ensure the uniformity of the surface is regained.

INSTALLATION

01 MASKING

Install Decobond in the same direction with the arrows printed on the masking. This is to avoid possible reflection differences among the installed sheets.

Only take off Decobond masking film after the installation is completed, taking off the masking during the installation might damage or scratch Decobond.

Remove the masking before 45 days, after that, it might be difficult to be removed.

Ensure to use the hand gloves while removing the masking film to ensure no finger print on Decobond surface.

02 Using Hollow Aluminum (without frame)

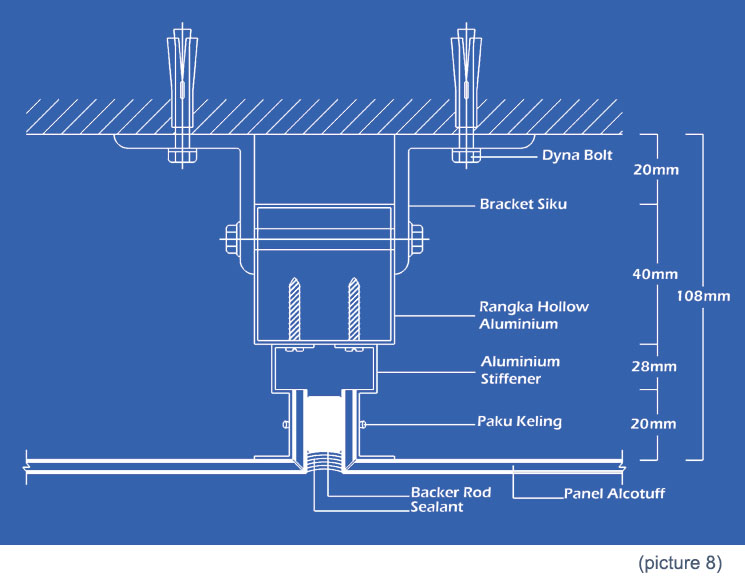

The method of mounting using aluminum hollow is to apply the hollow to the wall directly by using angle bar (3mm thickness) and Decobond will be applied to an aluminum hollow (min 1.2mm thickness) using a stiffener profile (3mm thickness and min dimension 4x4cm) instead of a spigot. (see picture 8)

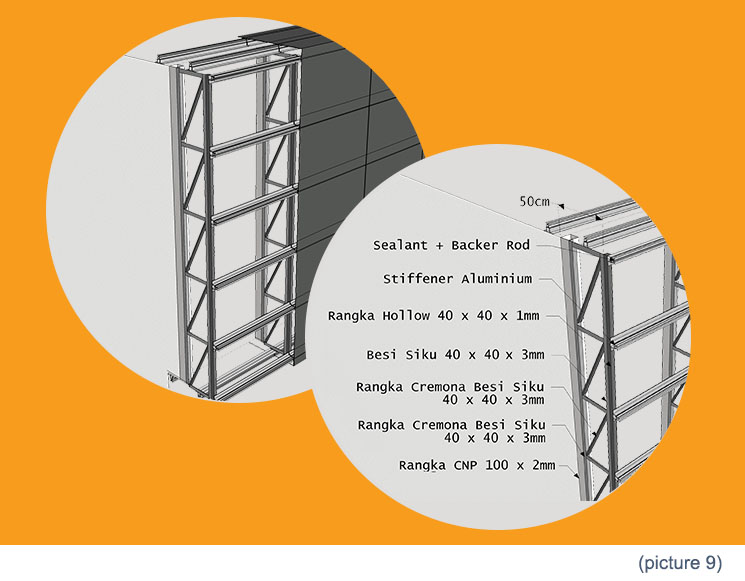

03 Menggunakan Rangka Cremona

The mounting method using the Cremona frame is using of angle bar (3mm thickness) as a supporting frame on the wall and Decobond will be mounted on a stiffener (3mm thickness) then it will be mounted on the Cremona frame. Usually, the installation method using the Cremona frame is carried out if the surface of the wall is uneven, the surface of the wall is not flat or has not been cemented.

The distance of the frame that connects Decobond to the wall is recommended between 20 cm – 50 cm. (see picture 9)

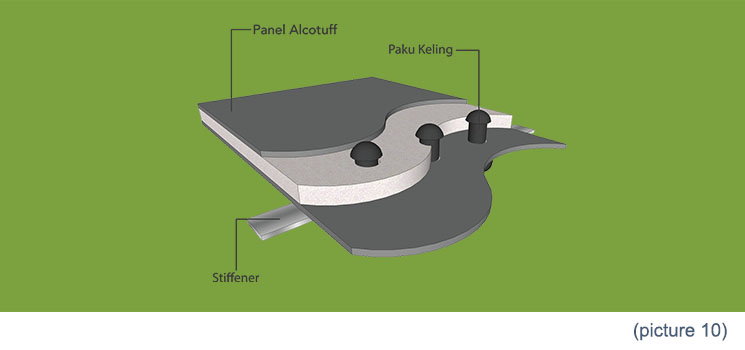

04 Riveting / Rivets

Decobond can be mounted on a stiffener by using rivets or commonly called the riveting method. (see picture 10)

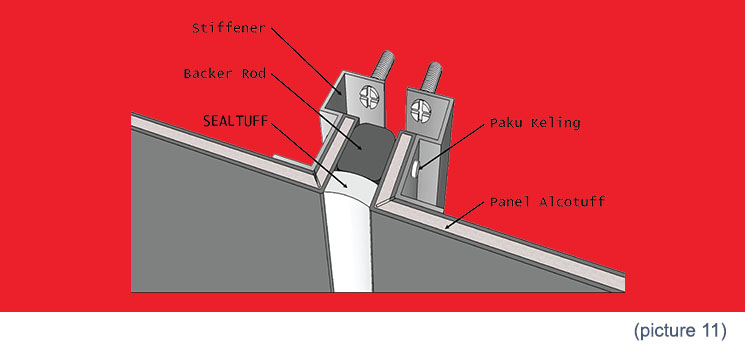

05 Sealant

Low to medium modulus sealant is recommended to close the gap between panels to ensure expected joint width movement capability is achieved.

The sealant applied over a foam back rod, the depth of the sealant is recommended half time of the width gap. (see picture 11)

For the best joining result, use SEALTUFF High Performance Hybrid Sealant.

CLEANING AND MAINTENANCE

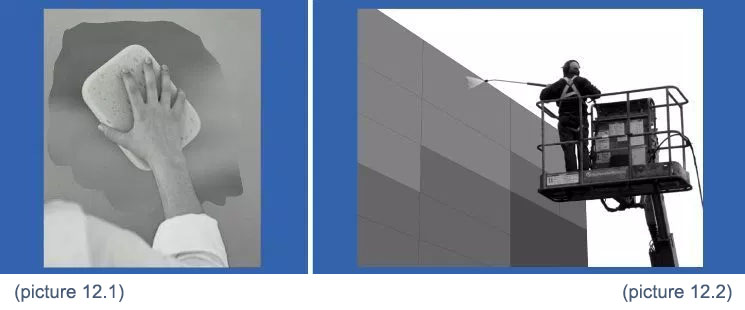

Regular cleaning and maintenance is necessary to preserve the color and ensure the durability of Decobond. At least an annual Inspection and cleaning is recommended, depending on the surrounding environment.

Decobond can be cleaned using a soft sponge or a high-pressure water (max 50 bar). If needed, max 10% mild cleaning agent at Ph 6-7 can be mixed in the water. A trial on a smaller surface is recommended to ensure that this liquid mixture doesn’t affect Decobond surface. (see picture 12.1)

Surface heated by the sun over 40 °C is not recommended for the cleaning process as the quick drying might cause blemishes all over the surface. Wait till the temperature goes down. (see picture 12.2)

STORAGE

Please keep Decobond in a dry place and away from the sun. Exposure to direct sunlight for long time might cause the difficulty to remove the masking film. Ensure the temperature stability of the storage place to avoid any condensation that might damage the surface of the sheet.

Store Decobond horizontally to avoid bending on the panel surface. When piling the sheet on a pallet, ensure to heap only sheets with the same sizes. It is also not recommended to stack the pallet one over the other. (see picture 13)