Alcotuff is composed of fire resistant core sandwiched between two architectural aluminum skins Though the core material does contain a small amount of combustible polyethylene, the main ingredient of the core contains the mineral that does not permit the spreading of flame and restricts the development of smoke detrimental to the evacuation process.

Yes, you can get your customized dimension, subject to minimum order quantity. For further information, please contact your nearest dealer or our customer service.

Yes, custom colors are available, subject to minimum order quantity. Upon receiving your color samples, it will take around two weeks for the color matching process. Once you approve and sign the matched color, it will take approximately another six weeks to get your sheet ready in our warehouse to be delivered to you place. For more information please contact your nearest dealer or our customer service.

This depends on your local building codes. However, most of the building codes require FR for construction of 15Metre high or 5 storeys and above.

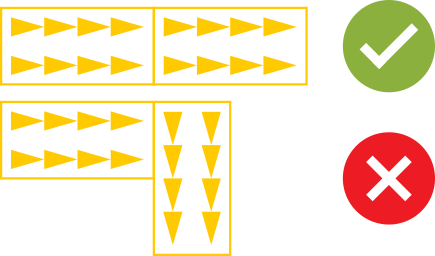

Slight shade difference might be noticeable if the panels are installed in different direction.

Prior to installing Alcotuff and Alcolite, please ensure that you identify the yellow arrows printed on the protective film.

Polyester coating is recommended only for indoor application or light outdoor application, while if you need to do the façade, exterior cladding, roofing, or any construction that will intensively be exposed under the sun and weathering, then you will need PVDF coating. PVDF is characterized with ultra-weatherability that will retard color fading for a long time period in outdoor condition, and is considered the standard for high-tech coatings in the construction industry, primarily on the strength of its excellent ageing stability.